Production

State-of-the-art technology thanks to the use of market leaders.

State-of-the-art technology thanks to the use of market leaders.

With our modern machinery and equipment, we are ideally equipped to manufacture all kinds of mechanical, high-precision turned, milled and drilled parts in small to medium series and from a wide variety of materials. Our list of machines and systems.

Please enter…

Machinery

Nakamura Super NTY3

1 turning center

12 axles

3 Revolvers

2 spindles

3 y-axes

Max. 56 tools, 36 of which are driven

Breuning bar feeder for 24-hour loading. Operation for bar work up to ø42 mm for complex turned, drilled and milled parts in medium batch sizes

Nakamura NTY3-150

1 turning center

12 axles

3 Revolvers

2 spindles

3 y-axes

max. 56 tools, 36 of which are driven

Breuning bar feeder for 24-hour operation

for bar work up to ø65 mm

for complex turned, drilled and milled parts in medium to large batch sizes

3x Biglia B436Y2

3 Turning center

9 Axles

2 revolvers

2 spindles

2 y-axes

36 Tools

Breuning bar feeder for 24-hour operation

for bar work up to ø36 mm

for complex turned, drilled and milled parts in medium batch sizes

2x Biglia B42SM

2 turning centers

7 Axles

2 revolvers

2 spindles

24 Tools

IEMCA bar feeder for 24-hour operation

for bar work up to ø42 mm

for complex turned, drilled and milled parts in medium batch sizes

Miyano BNJ42S

1 turning center

6 axles

Subspindle

Driven tools

Automatic charger for 24-hour operation

for bar work up to ø42 mm

for complex turned, drilled and milled parts of medium to large dimensions

Lot sizes

Miyano BNA-DHY

1 turning center

2 revolvers

Y-axis

Driven tools

Automatic charger for 24-hour operation

for bar work up to ø42 mm

for complex turned, drilled and milled parts of medium to large dimensions

Lot sizes

Brother TC-S2DN

Vertical machining center

Table size: 800×400 mm

Travel X,Y,Z: 700x400x300 mm

Spindle speed: 16,000 rpm.

max speed thread cutting: 8’000 rpm.

Tool places: 21

Chip to chip time: 1.6 s

4th axis: Turntable ph Lehmann

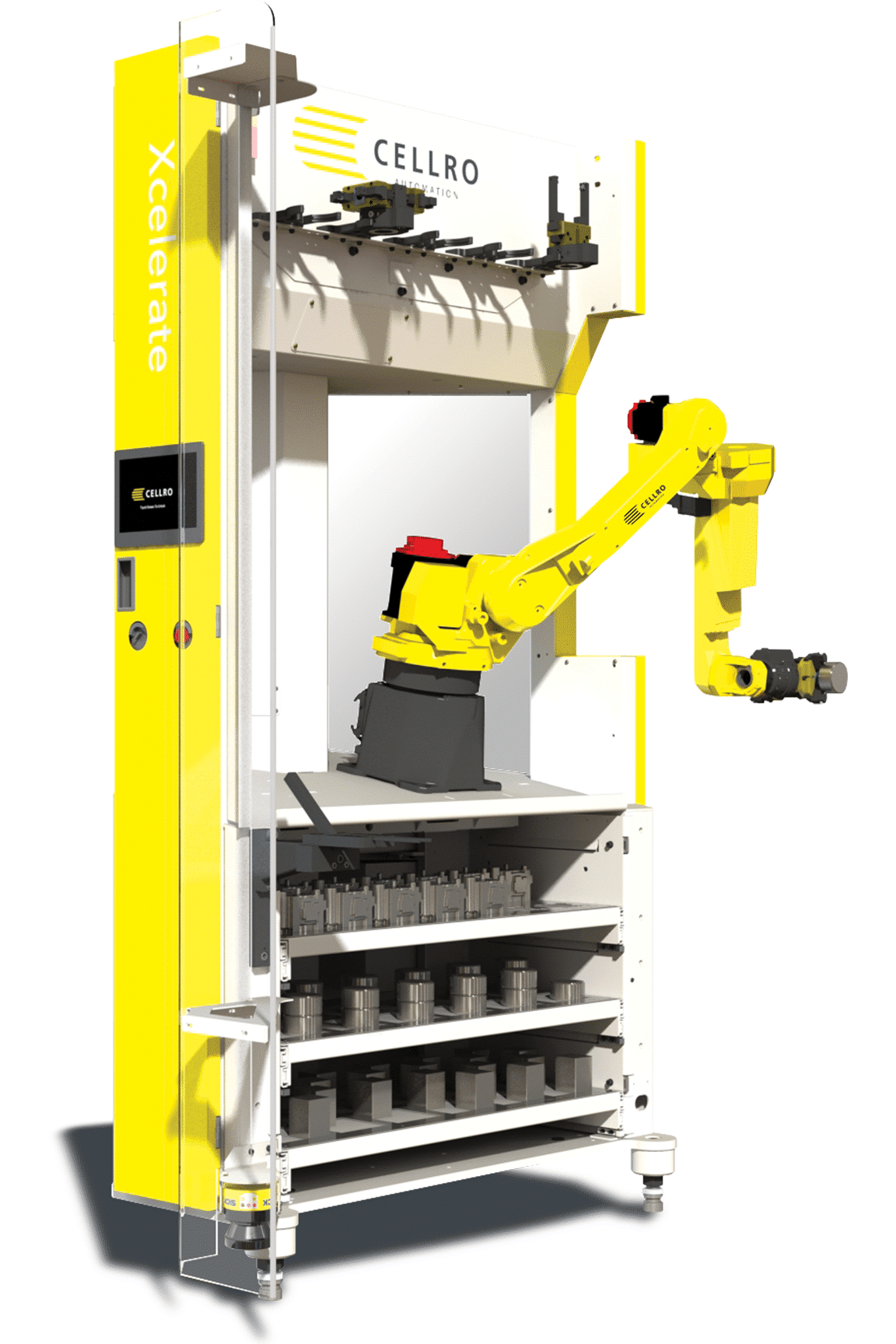

Cellro X10

Mobile automation solution

Our “Klimatower” – Guaranteed clean air for man and machine

Reference object!

Please contact Technorobot AG for a non-binding viewing:

TECHNOROBOT WELDING AG

Bischofszellerstrasse 77

CH-9200 Gossau SG

Tel. +41 (0)71 505 15 15

Kardex Remstar Shuttle XP500

Automated high-bay warehouse

- Mainly used for storing finished parts

- Permanent monitoring and guarantee of low humidity

- Highly efficient storage and retrieval

- Optimized warehouse workflows through interface solution to the ERP system

- Device height: 9.5 m

- Device width: 3.2 m

- Device depth: 2.9 m

Faudi Fufav 4.5/1500 central cooling lubricant system

Vacuum filter system

- Tank volume: 11,000 liters

- Filter area: 7.5m2

- Emulsion content: 5-8%

- Operating temperature: 20±1°

Coordinate measuring machine Mitutoyo Crysta-Apex V91006 CNC

Economical high-performance CNC coordinate measuring machine

- Portal design with high rigidity.

- Air-bearing guides in all axes

- High accuracy

- High travel speed (519 mm/s) and acceleration

- Integrated thermal error compensation including workpiece with 2 contact temperature sensors

- Measuring range:

X = 900 mm

Y = 1’000 mm

Z = 600 mm